Toyota, the big Lean example, talks in The Toyota Way 2001 about Continuous Improvement & Respect for People.

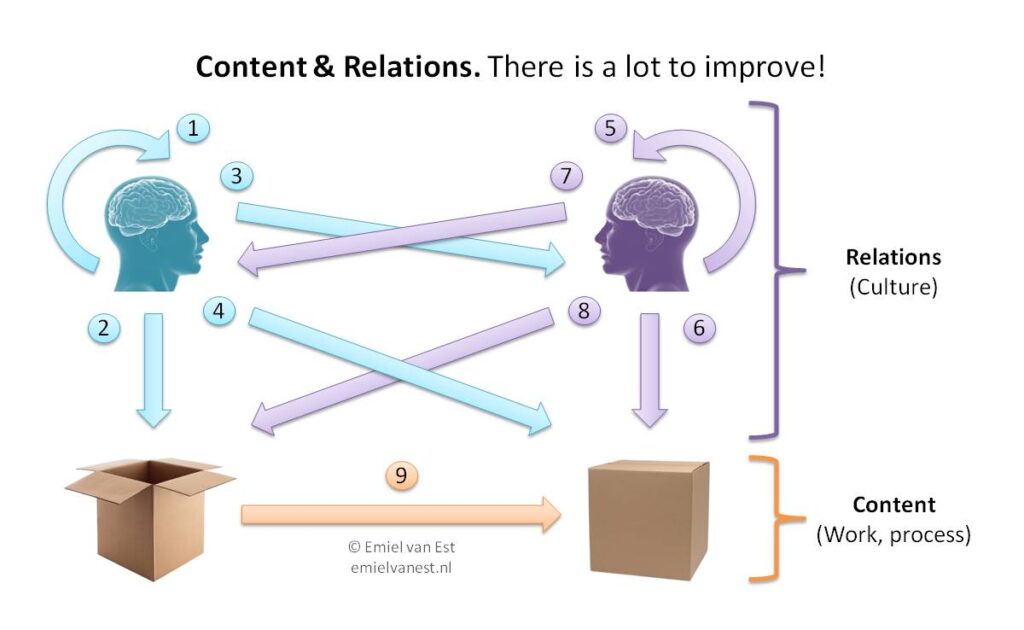

Recently I started talking about Content & Relations as a simpler introduction to these big topics of Continuous Improvement & Respect for People. It seems to work quite well!

Content

Traditionally Lean is quite strong on the content side. There are a lot of tools that one can use to address work related problems and process related problems. A lot has been published about that so I will not elaborate too much about that. Just note that flow is about the relation (9) between one piece of work content and the next one.

Reflection

If your only problems would be on the content level you should be very happy! Problems on the content level usually do not lead to a lot of conflict. Facts are facts. And, there are loads of tools to deal with these facts.

How you deal with these facts is a whole different story. If problems on the content level do not get resolved satisfactory it is very likely that the root cause of that is on the relations level.

The shop floor reflects the quality of the relations among people.

Relations

Relations abound in an organisation. The more people, the more relations. In the image above I show the relations of the smallest building block of an organisation: two interdependent people. Let’s assume the first person is you and the second person is your co-worker.

1) How do you relate to yourself?

We all have our history, we all have our moods. If you have a difficult relation with yourself that will have a strong influence on all the other relations that you have.

2) How do you relate to your work?

Is this the work that you were born to do? Do you hate the work you do? Just the content side of it, not all that other stuff going on.

3) How do you relate to the other?

Is you co-worker your friend? Do you like the company of your co-worker? Or are you going out of your way to avoid a conversation?

4) How do you relate to the other persons work?

Do you value it? Do you envy it? Do you feel disdain about it?

5) How does the other person relate to themselves?

Sometimes the other person is just in a bad place. They may have problems at home or some other issues you may not know about. Or they may be the Zen master of calm.

6) How does the other person relate to their work?

Do they love it? Do they hate it? Is it just what pays the bills?

7) How does the other person relate to you?

You may want to build a good relation but the other person may show no interest at all. Or the other way around.

8) How does the other person relate to your work?

With appreciation? With envy? With disdain?

Where to start?

It is always safe, a good idea actually, to start working on the relation you have with yourself.

Apart from that, I would suggest you start your improvement efforts on the content level. That should be quite safe. As long as you can make progress in this way; keep going!

If it is not safe or you encounter all kinds of difficulty that seem to be unrelated to the content, than there is probably a problem in one or more of the relations mentioned above.

How to deal with these problems? That is a good question.

Lean does not have a great toolbox to deal with relation issues…

Now you are entering the domain of neuroscience and psychology. In cooperation with David Bovis I created an A3 to help resolve relationship problems. Maybe a topic for a next post!

Dave Outlaw says

This is a team building exercise that requires a an individual preference assessment . We use them in HR to find a candidate that fits the existing team as we need to have diversified thinking

Emiel van Est says

I do not think this is very useful in a hiring situation because the relations have yet to build. I think this framework is more useful when issues arise in the cooperation. I also tend to see this more for a one on one reflection than as a team building exercise.

Feike Oosterhof says

I think there is some power in “Go and see”. As the English put it so very ‘eloquently’: “Assumptions are the mother of all fuckups”. Relations can become stronger with insight in another man’s work, circumstances and processes.

Emiel van Est says

I think it is important to go and see first, go to the gemba, because the shop floor will reflect the qualities of the relations.

Regarding assumptions: we do not just have assumptions about the work and processes but also about other people…